Vicon RV 5216 FW Plus

Combinación de empacadora y encintadora

Combinación de rotoempacadora y encintadora con concepto de empacado de cámara variable con un diámetro de paca de 0,60 a 1,65 m.

Descripción

Al igual que los modelos de empacadora individual, las combinaciones de rotoempacadora y encintadora Vicon RV 5216 Plus FlexiWrap han recibido mejoras. Estas mejoras tienen como objetivo aumentar la productividad y reducir los requisitos de mantenimiento, disminuyendo los gastos de explotación. La Vicon RV 5216 Plus FlexiWrap tiene un sólido chasis de eje tándem que garantiza una estabilidad excepcional. El chasis ha sido rediseñado e incluye una nueva barra de tracción y amplios detalles para reducir la acumulación de forraje. Además, se ha mejorado el equipamiento de las ruedas y los controles son ahora compatibles con ISO.

Puntos clave

Solución integrada para empacar y envolver de una sola vez

La mesa de envoltura se transfiere al portón trasero de la rotoempacadora

Enfardado de alta velocidad con dos pretensores

Las varillas de film adicionales se bajan hidráulicamente para facilitar el cambio

Baja altura de la mesa para una descarga suave de las pacas

Características

Fast Acting Net Cycle

FixBale 500 is equipped with the patented front mounted PowerBind net system.

PowerBind eliminates troublesome feed rollers and has market leading cycle time.

Minimum Time Stationary – Maximum Time Baling

The net is continuously retained in the PowerBind injection arm. When the bale is 90% complete the arm moves forward ready for the net injection.

When the bale is 100% complete net is fed directly onto the bale in a flat movement angle keeping the net tight at all times, providing accurate and extremely reliable net injection.

PowerBind gives you the confidence of doing a professional job, without influence from wind or crop build-up.

Low Net Loading Height

PowerBind offers very low loading height for maximum convenience and time-saving.

To replace the empty roll just swing out the shaft and slide on a new roll.

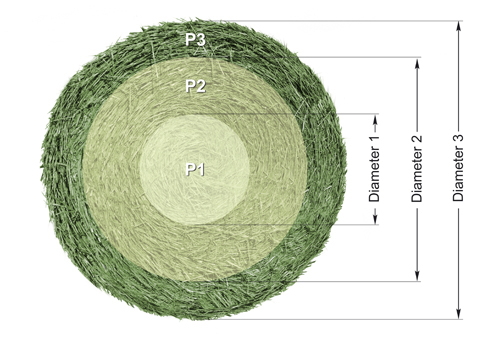

- Setting and selection of correct bale density is vital in order to get the right quality of the bale. Especially when the baler is utilized through the full season in different crops like straw, hay and silage it is important to adjust the bale density to the specific type of material.

- Intelligent Density 3D with 3 pre-selected bale density settings making it very easy to choose the correct bale density in different crops.

- It is however still possible to customize the bale density in 3 separate zones each with a choice of diameter and pressure to match specific requests.

- With the new Intelligent Density 3D application, three pre-configured bale densities are available from the menu of the control box, each of them tailored for straw, hay or silage. This makes the change-over from different crop materials much easier limiting the risk of mistakes.

- Baling dry straw and want the heaviest bales possible? Maximum pressure is set in every zone.

- Baling hay? The soft centre core is set to let the bale breath, with gradually increasing pressure towards the outer layer.

- Baling wet silage? Pressure is reduced in the centre and mid zones.

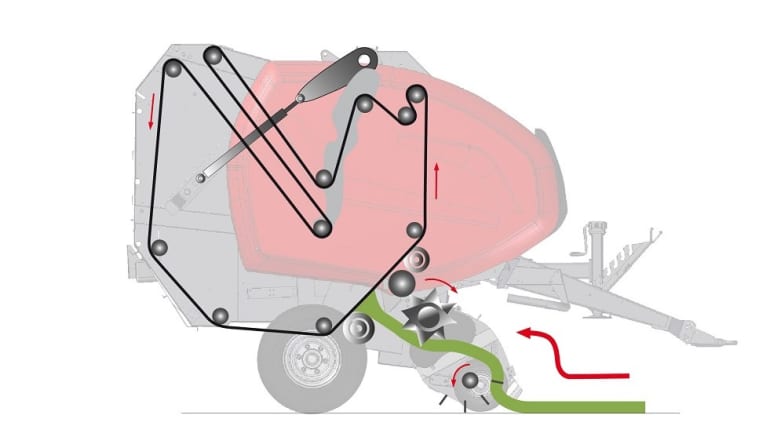

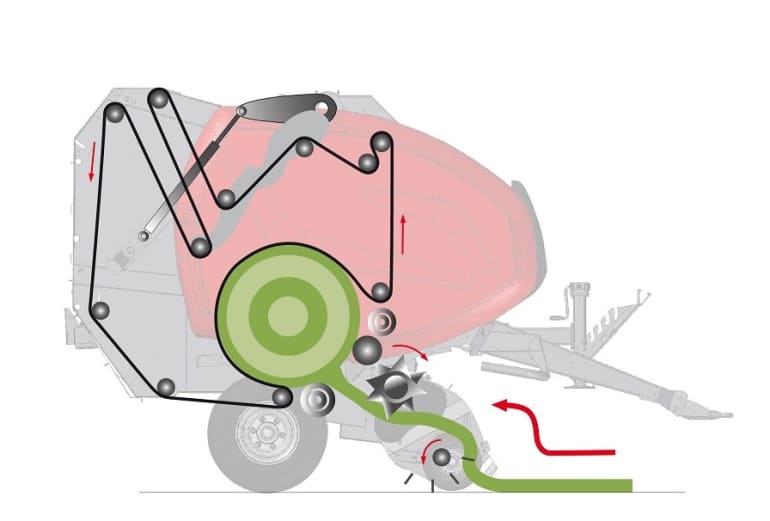

- Once the net is applied to the bale the wrapping table is transferred to the tailgate of the baler unit, ready to receive the finished bale.

- When the tailgate opens the bale is dropped directly onto the wrapping table, with no interfering steps in-between that needs to guide the bale onto the wrapping table.

- This provides a very safe bale transfer with no risk of the bale rolling off the wrapping table, even when working in very hilly conditions.

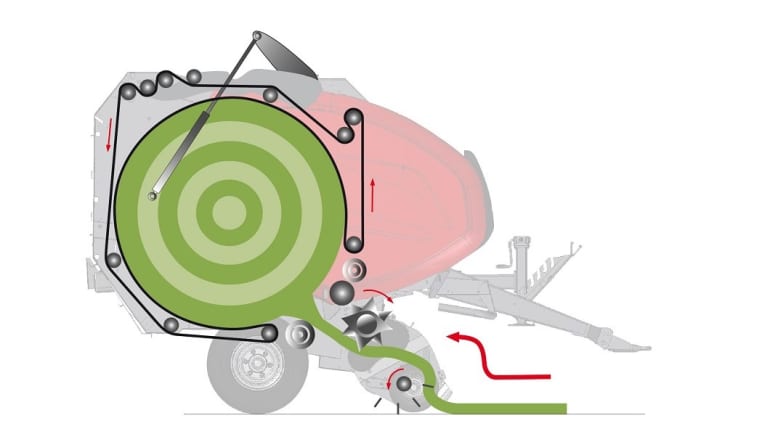

- When the bale is onto the wrapping table it is transferred quickly to the satellite wrapper, and wrapping starts instantly.

- The wrapping table with 4 endless belts and rollers carries and rotates the bale evenly during wrapping with no risk of film damage.

- The twin pre-stretchers ensure high-speed wrapping, so the wrapping process will finish on time before the new bale is ready.

- The pre-stretchers are positioned close to the bale, to limit the amount of air trapped under the film during wrapping.

- Once the bale is wrapped, it can be unloaded automatically or manually during the formation of the next bale. The manual option gives the driver the possibility to drop the bale where most suitable, for instance so bale are all dropped in line for each pick-up.

- The low-mounted wrapping table ensures gentle unloading of the bales. In addition the ViconFlexiWrap can be fitted with a bale on end kit. The bale is tipped off gently on the end side, where the highest number of film layers is applied.

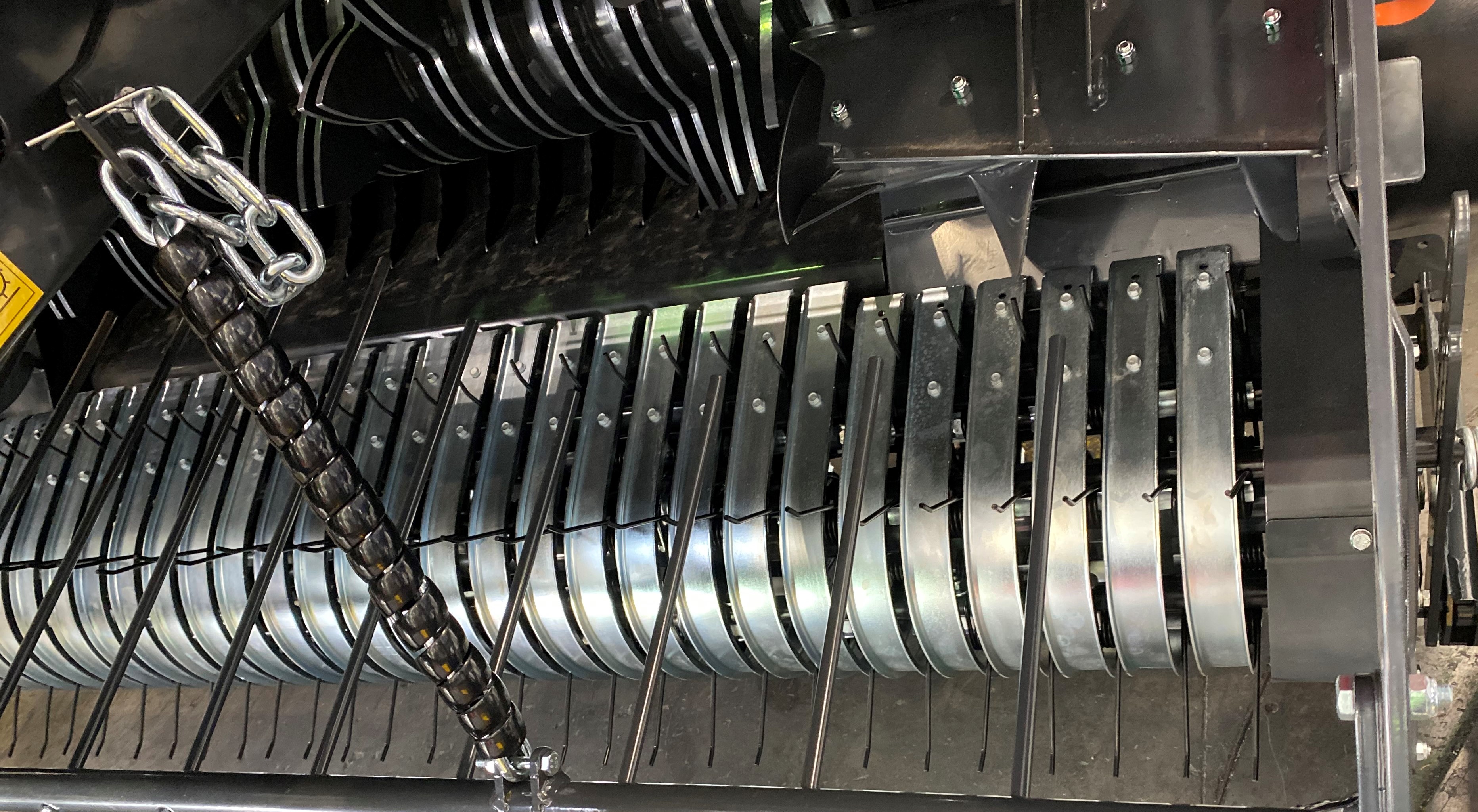

- 2.2m pick-up with small diameter pick-up reel for fast and efficient throughput.

- Pick-up with 5 rows of tines

- Twin cam tracks

- Tine bars with two central supports.

- Small diameter pick-up design.

- Roller crop press is standard.

- Narrow transport width – no need to remove the pick-up wheels for transport.

SuperCut-25

- The SuperCut-25 pre-chopping system offers the ultimate solution for short chop baling with a chop length of 40mm. The short and precise chop provides dense and airtight bales for the best possible silage quality.

- The operator can choose to engage 25, 13, 12, 6 or 0 knives, giving maximum flexibility of operation.

- The SuperCut- 25 knives are fitted with dual action protection against foreign objects. Each knife is individually spring protected and can move in two directions

SuperCut-14

- The SuperCut-14 knife chopping system provides a fast and efficient flow into the baler. With a chopping length of 70 mm it is the ideal solution for producing tight bales with superb silage quality.

- Each individual knife is spring protected against foreign obstacles. The knife will immediately return to its working position once the obstacle has passed.

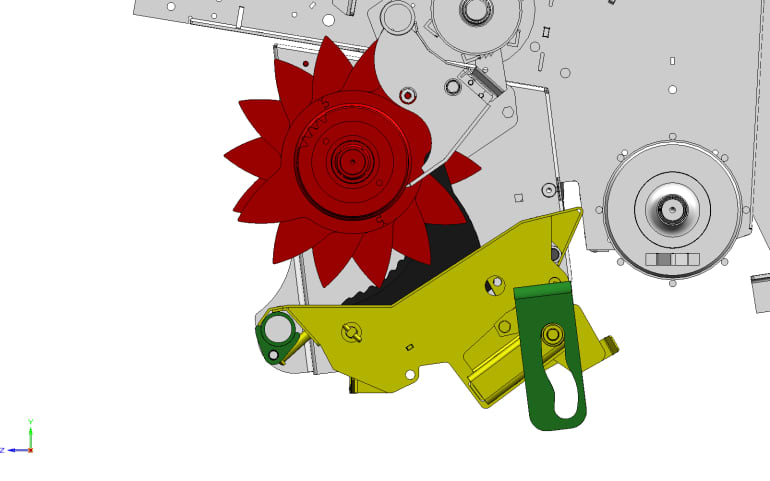

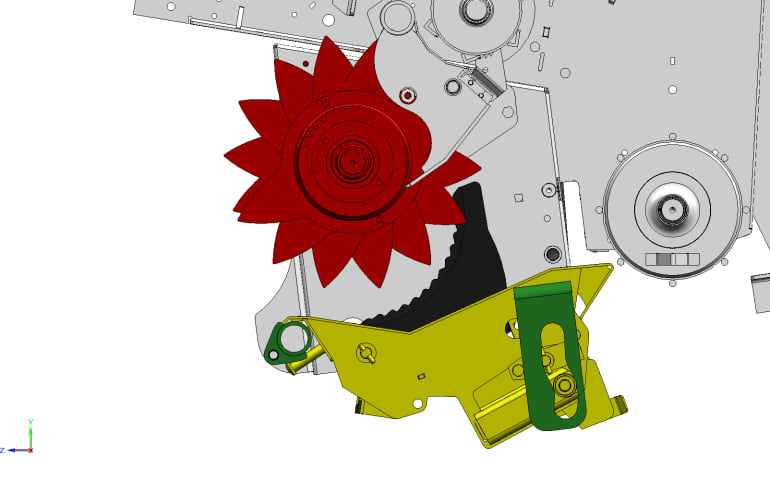

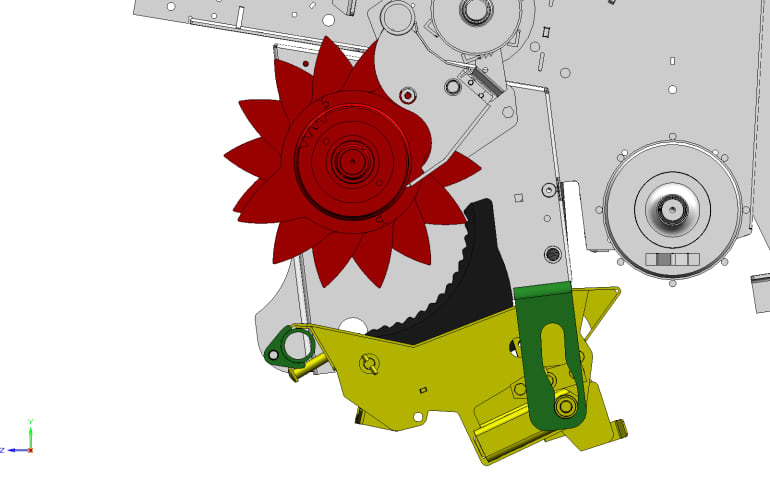

PowerFeed Rotor Intake

- Truly impressive intake capacity can be achieved with the PowerFeed rotor intake system - handling all crop types with ease, whatever the conditions.

- The PowerFeed rotor with its 13 rotor fingers proactively forces the material into the bale chamber for higher intake speed and capacity proving instant bale start.

Parallelogram DropFloor System for faster Unblocking

Parallelogram Drop Floor enables the operator to clear blockages easily from the tractor cab without any crop loss.

Drop the floor to free the rotor of blockage, engage the PTO to feed the blockage through and close the floor to continue baling.

- The FlexiWrap baler wrapper combination is firmly mounted onto a strong and durable chassis.

- Load and weight are evenly distributed for maximum stability, for instance thanks to the low position of the wrapping table.

- The tandem axle with 560/45-R22.5 tyres (optional 710/35-R22.5) provides very good stability when operating in the field or running on the road.

Características técnicas

Características técnicas

Descargar catálogo| RV5216 Plus SC14 FW | RV5216 Plus SC25 FW | ||

|---|---|---|---|

| Tamaño de paca (m) | 1,20 x 0,60 a 1,65 | 1,20 x 0,60 a 1,65 | |

| Alimentación | Picador SC14 | Picador SC25 | |

| Atado | Red | Red |

Características técnicas

Características técnicas

Descargar catálogoRV 5216 FlexiWrap SC-14 |

RV 5216 FlexiWrap SC-25 |

RV 5220 FlexiWrap SC-14 |

RV 5220 FlexiWrap SC-25 |

|

Bale Size (m) |

1.20 x 0.6-1.65 |

1.20 x 0.6-1.65 |

1.20 x 0.6-2.00 |

1.20 x 0.6-2.00 |

Bale Chamber |

5 belts/3 rollers |

5 belts/3 rollers |

5 belts/3 rollers |

5 belts/3 rollers |

Pick-Up (m) |

2.20 |

2.20 |

2.20 |

2.20 |

Cutting Device |

SuperCut-14 |

SuperCut-25 |

SuperCut-14 |

SuperCut-25 |