Vicon BW 2100

Encintadoras | Encintadoras de mesa

La BW 2100 es ideal para operaciones de "encintar y apilar"

Encintadora de rotación de mesa suspendida

Descripción

La serie Vicon BW2100 es una encintadora suspendida, ideal para operaciones de 'encintado y apilado en la explotación' cuando la paca se transporta al lugar de almacenamiento para su encintado. Puede engancharse en el tripuntal trasero o delantero del tractor o utilizarse como máquina estática con un grupo electrógeno externo. El modelo Vicon BW2100 se puede configurar con un pretensor simple o con un pretensor de doble película de alta velocidad High Speed Pack (HSP).

Puntos clave

- Encintadora de rotación de mesa suspendida en tres puntos

- Solución ideal para el encintado en el lugar de almacenamiento.

- Capaz de manipular pacas de hasta 1200 kg de peso.

- Variante de alta velocidad High Speed PAck (HSP) opcional para un encintado más rápido.

- Control total por ordenador, incluido un mini joystick para control manual.

Características

Características

- El volteador de pacas (Bale Turner) garantiza que las pacas se descarguen por su lado plano, lo que ofrece una mayor protección contra daños pues acumula más espesor de plástico.

- El paquete de alta velocidad (HSP) garantiza la velocidad de encintado óptima y elevada, como resultado de los sistemas combinados Optispeed y del doble preestirado DuoWrap.

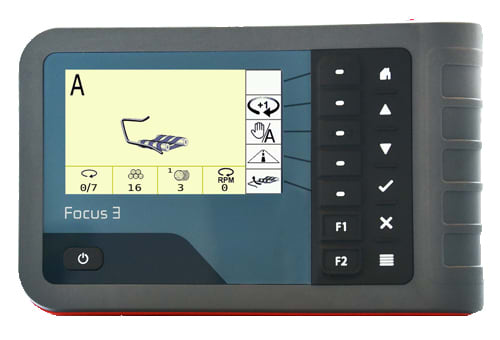

- Control por ordenador (C): Funcionamiento totalmente automático o semiautomático

- Hay disponible una versión avanzada con control remoto en las versiones C de las encintadoras. Se coloca la paca en la encintadora, se pulsa una tecla del mando a distancia y se iniciará el proceso de envoltura.

- El accionamiento hidráulico consigue un corte y sujeción precisos.

- Corta y sujeta la película de manera eficiente para el siguiente ciclo.

- El pretensor mantiene una tensión constante en todo el rollo para conseguir el solape apropiado y la activación de la adhesividad del film

- Pretensor doble DuoWrap/HSP para un encintado más rápido.

- El estiramiento uniforme de la película reduce el riesgo de desgarro.

- Sistema de carga de bobinas con una sola mano.

- Encintado estable y descarga suave

- Altura de carga/descarga baja que reduce el riesgo de daños en la descarga.

- La plataforma giratoria cuenta con dos rodillos accionados diseñados para ofrecer gran estabilidad de las pacas y una rotación suave y uniforme.

- En los modelos BW 2100, BW 2400 y BW 2600 un cortador de plástico operado hidráulicamente corta el film y lo sujeta para hydraulically operated film cutter cuts and holds the film in position ready to wrap the next bale.

- An easy to use solution without the need to manually control the operation.

- Two large diameter rollers, both of which are driven, ensure bale rotation even in the most difficult conditions.

- Four endless belts carry and rotate the bale evenly during wrapping with no risk of film damage.

- The two large diameter conical side support rollers ensure that the bale is kept in a central position on the rotating table during wrapping operation.

Computer Control (C)

- The computer controlled Model C turns the wrapper into a fully automatic machine offering either a fully automatic operation or a choice of manual override or function by function operation.

- Choose for example that you want the bale to wrap automatically off. One operator does the entire process of loading, wrapping and stacking when loaded, but remain on the wrapping

- table until you confirm that you want to offload.

Remote Control (R)

- An advanced remote controlled version is available as an option (standard on BW2100 C). Place the bale on the wrapper, press one key on the remote control, and the wrapping process starts.

- The previously wrapped bale is stacked and the next one picked up while the machine continues wrapping.

- Press another key when wrapping is completed and the bale is tipped off. One operator does the entire process of loading, wrapping and stacking.

Joystick Control (J)

- The semi-automatic Joystick model has a handy electric joystick combined with a control box which is showing you the operations running at any time.

- Functions like bale and wrap counter and automatic table stop when reach ing pre-set number of table revolutions are included as standard.

Mechanical Cable Control (M)

- The manual versions (M) are controlled with manual cable control with levers.

- A wrap and bale counter is fitted for easier control of film layers, as well as number of bales wrapped.

- An automatic table stop that is controlled by the wrap-and-bale counter is fitted as standard.

- This converts the wrapper from manual to semi-automatic, as it allows the wrapping function to stop automatically at the set number of table revolutions.

The DuoWrap sees twin film dispensers integrated into the Vicon BW 2100, BW 2400 and BW 2600 mounted and trailed turntable wrappers. DuoWrap gives up to 50% faster wrapping compared to single film models, whilst also reducing the risk of film breaking during wrapping. Utilising a 66% overlap of the two films as they are applied to the bale, DuoWrap ensures even coverage without excessive wrinkling of the film.

El sistema HSP es la combinación de dos desarrollos. Por un lado DuoWrapp, que permite encintar con dos bobinas simultáneamente con un solape del 66%, con lo que se reduce en 1/3 el tiempo empleado para envolver una paca. Por otro lado OptiSpeed, un control electrónico de la velocidad de rotación de la paca.

OptiSpeed optimiza la velocidad de giro de la mesa de encintado manteniéndola en el máximo posible y ajustándola, entre unos parámetros predeterminados, a las condiciones de trabajo.

HSP está disponible para las encintadoras BW 2100C y BW 2600C.

Características técnicas

Características técnicas

Descargar catálogo| BW2100 C | ||

|---|---|---|

| Tamaño máximo de paca (m) | 1.20 x 1.50 | |

| Peso máximo de la paca (kg): | 1200 | |

| Función de control: | Control por ordenador |

Características técnicas

Características técnicas

Descargar catálogoMáx. tamaño paca |

Máx. peso paca |

Sistema control |

|

BW2100 |

1,20 x 1,50 m |

1.200kg |

Ordenador (C) |